Shot blasting of concrete floors: a detailed guide

Shot blasting is a widely used method for preparing concrete floors, ensuring a durable final finish. Whether you are getting ready to apply paint or other coatings, or simply want to improve the floor’s texture, shot blasting provides a highly effective solution. In this article, we will explore what shot blasting is, how it works, and the benefits it offers for concrete floors.

What is shot blasting?

Shot blasting is a mechanical surface preparation process that involves treating the concrete surface (usually with steel shots). This process cleans, levels, and profiles the concrete, creating the perfect surface for adhesives or paints to bond. It is often preferred over traditional methods such as acid etching or grinding due to its precision, efficiency, and versatility.

Shot blasting is typically performed with a specialized machine. The steel shots are propelled onto the concrete surface using centrifugal force and are then collected and recycled in a closed-loop system. This process effectively removes dirt, grease, old coatings, and surface defects, while simultaneously profiling the concrete to the desired texture.

How does shot blasting work?

The shot blasting process involves several steps to ensure thorough and effective floor preparation:

- Surface cleaning: The first step is cleaning the floor of dust, debris, oil, grease, or loose material that could interfere with the shot blasting process. This ensures effectiveness and the desired result.

- Abrasive blasting: The shot blasting machine propels abrasive steel shots at high speed onto the floor surface. When these tiny particles hit the concrete, they create a mechanical scouring action that both cleans the surface and creates a porous texture.

- Recycling: After impact with the floor, dust and shots are vacuumed into the machine’s collection system, which separates dust from the shots. The recycled shots can then be reused, making the process cost-efficient and environmentally friendly.

- Final cleaning: After shot blasting, the surface may be vacuumed if necessary, leaving a clean, profiled surface ready for further treatment.

Benefits of shot blasted concrete floors

Shot blasting offers several advantages when preparing concrete surfaces:

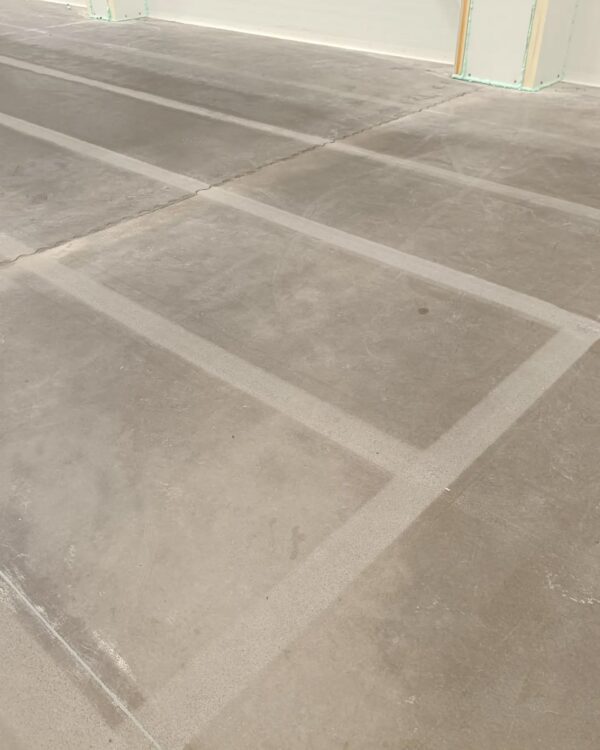

- Excellent surface profile: Shot blasting creates a uniform texture that promotes strong adhesion for coatings, paints, and overlays. This ensures that each subsequent layer bonds firmly and lasts longer.

- Dust-free and low-vibration: Unlike grinding, shot blasting produces minimal dust thanks to its closed-loop return system. This makes it a cleaner and healthier alternative, especially in enclosed spaces. Additionally, it generates relatively low vibration, reducing strain on both equipment and operators.

- Effective contaminant removal: Shot blasting can remove a wide range of surface contaminants, including old coatings, paints, adhesives, oils, and greases. It also helps eliminate defects such as small cracks or surface irregularities, resulting in a more even floor.

- Speed and efficiency: Shot blasting is a fast and efficient method compared to grinding or acid etching, saving time in surface preparation. On large concrete surfaces, it can significantly reduce preparation time.

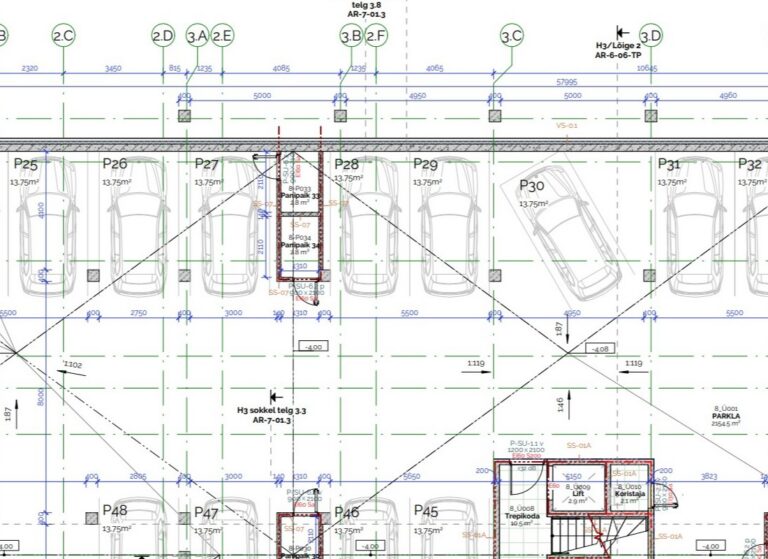

- Versatility: Shot blasting can be used on various types of concrete floors, including warehouses, industrial facilities, parking garages, and even decorative concrete surfaces. It is suitable for preparing floors for treatments such as epoxy and polyurethane coatings or floor marking paints.

- Eco-friendly: Because the abrasive material is recycled throughout the process, shot blasting generates less waste compared to other methods. It also doesn’t rely on chemicals or harsh abrasives, making it a more environmentally friendly option.

Considerations for shot blasted concrete floors

While shot blasting offers many advantages, there are a few considerations to keep in mind before deciding if it’s the right choice for your project:

- Surface preparation requirements: The required level of surface profile determines whether shot blasting is the best method. For very smooth finishes, shot blasting alone may not suffice, and additional grinding may be needed. On the other hand, for medium to heavy coatings or epoxy layers, shot blasting usually provides the perfect roughness.

- Equipment and expertise: Shot blasting requires specialized equipment and should be performed by trained professionals. Improper machine use or the wrong abrasive material can result in uneven profiles or damage to the concrete. Renting the right equipment or hiring experienced contractors is essential for proper execution.

- Potential surface damage: While shot blasting removes contaminants and minor imperfections, careless use can cause damage. The process may create small microcracks or pits in the concrete if performed too aggressively, especially on older or weaker floors. Assessing the condition of the concrete before starting is crucial.

- Noise levels: The loudest part of the process is usually the vacuum system. Workers should wear hearing protection to safeguard against noise. Depending on the size of the area, additional safety measures may be necessary to protect workers.

- Not suitable for all floor types: Shot blasting may not be the best choice for polished concrete floors or decorative finishes requiring a smoother, finer texture. It is most effective on floors requiring industrial-grade preparation.

Conclusion

Shot blasting is a highly effective method for preparing concrete floors, delivering excellent surface profiles and reliable results. Its ability to clean, profile, and prepare a wide variety of surfaces makes it an ideal choice. Whether you are getting a floor ready for a new epoxy coating or simply refreshing an old surface, shot blasting provides a cost-effective and eco-friendly solution. However, as with any surface preparation technique, it’s important to assess the specific needs of your project before deciding if shot blasting is the most suitable option.